Biomaterials - Chitosan

The Most Promising Biomaterial of 21st Century

What is a Biomaterial?

A Biomaterial is a substance that has been engineered to interact with biological systems for a medical purpose, either a therapeutic (treat, augment, repair or replace a tissue function of the body) or a diagnostic one. The performance and success of a medical device depend on the property of its key biomaterial ingredient. So, the selection of proper biomaterial plays a crucial role in the development and manufacturing of a medical device.

An ideal Biomaterial for medical devices should have features including: Bioactive, Biocompatible, Non-toxic, Non-corrosive, Bio-inert, Bio-adoptable and Sterilizable.

Biomaterials are grouped into four different classes as Polymers, Metals, Ceramics and Composites which can be utilized alone or in combination with each other to develop most of the commercially available medical devices. Biomaterials show promising activity in medical device development because of the ease of material fabrication, wide flexibility, and biocompatible nature as well as their broad range of electrical, mechanical, chemical and thermal behaviours.

Types of Natural Biomaterials

Chitosan

Collagen

Cellulose

Starch

Gelatin

Alginate

What is Chitosan?

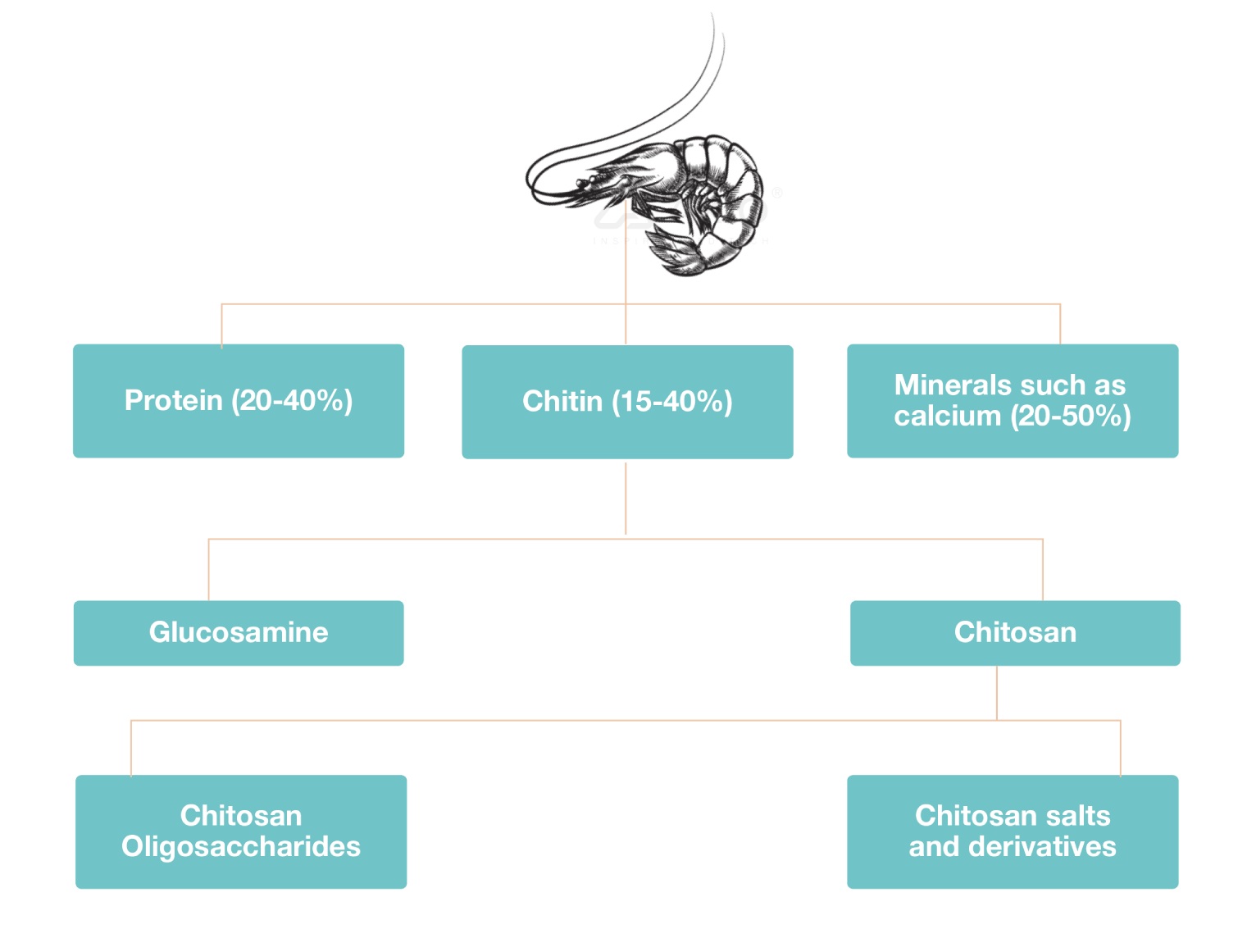

Chitosan is considered as one of the most promising biomaterials of the 21st century on accounts of its versatile nature, excellent biodegradability, biocompatibility, antimicrobial activity, non-toxicity and wide applications. Chitosan is derived from Chitin, a second most abundantly available natural polymer after cellulose.

Chitin is naturally found in the exoskeleton of shellfish such as crabs and shrimps, and in the cell membranes of fungi, yeasts, and other microorganisms. Chitin is not soluble in dilute acids, whereas chitosan is soluble in dilute acids.

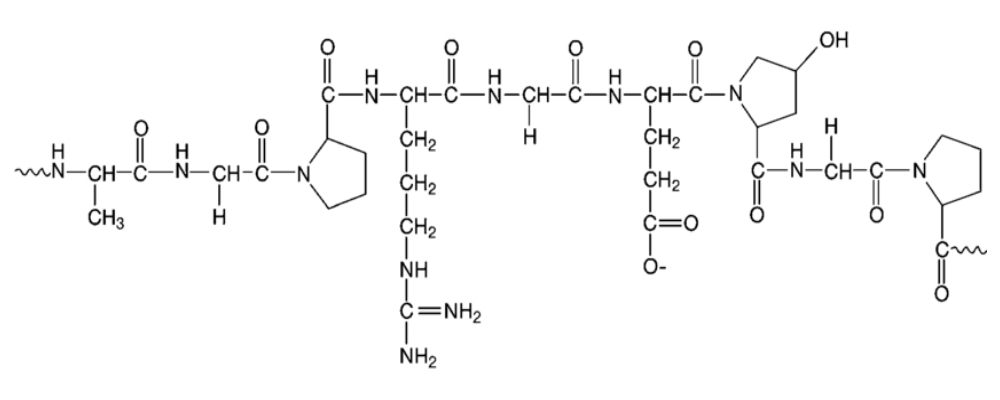

Chitosan is primarily composed of glucosamine and N-acetyl glucosamine residues with a 1, 4-β-linkage. The presence of primary amines (-NH2) in chitosan gives it a net positive charge and is important for its biological properties.

Molecular structure of Chitosan

- Currently, Chitosan is one of the most studied and frequently investigated biomaterials

- When the Degree of De-Acetylation(DDA) and nitrogen content in chitin exceeds by 50% and 7% respectively then it is called chitosan

- Crustacean waste is considered as a major source of chitosan for its commercial exploitation

Chitosan Facts

- Chitosan is derived from Chitin. It was the first polysaccharide identified by scientists, even before the discovery of cellulose

- Henri Braconnot isolated Chitin from mushrooms in 1811 for the first time

- The name of ‘Chitin’ is derived from the Greek word “Chiton” which means wrap.

- In 1859, Prof C. Rouget heated Chitin in presence of an alkaline medium for the first time and discovered ‘Chitosan’

- The word ‘Chitosan’ was coined by Hoppe-Seyler in 1894

Worldwide Distribution of Chitin and Chitosan in Nature

- Chitin is naturally distributed in the endoskeleton of Cephalopoda, the exoskeleton of arthropods and the cell membrane of fungi and plants.

- Each year 6-8 million tons of Crustacean waste produced globally from the shells of shrimp, crab, lobster, and squid

- Production of chitin from marine sources are identified in the countries such as India, China, Japan, Poland, Australia, the United States and Norway

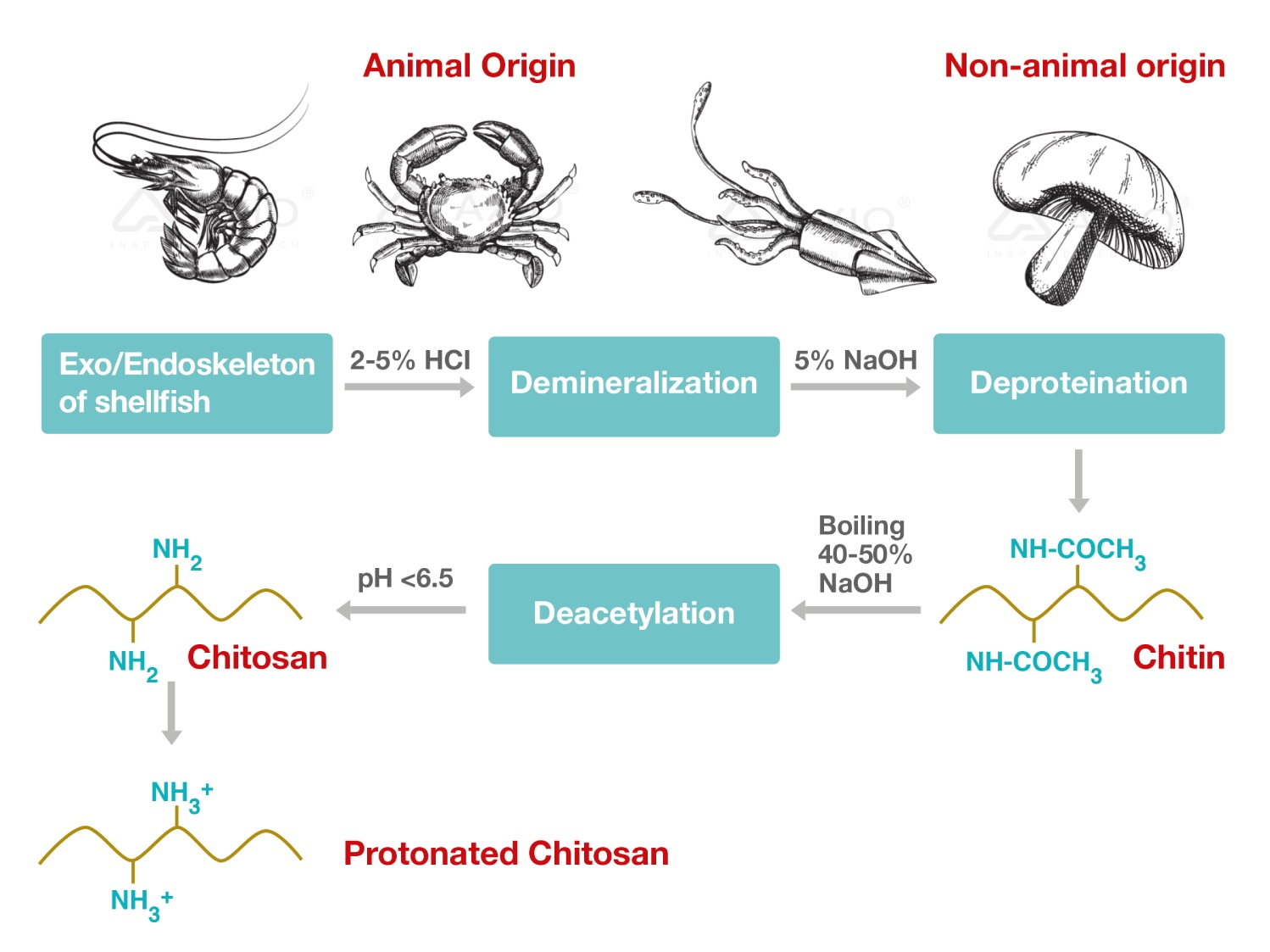

Chitosan Extraction

The production of chitosan starts with the selection of a suitable source for chitin extraction. Chitin can be extracted from either the animal sources such as shellfish or non-animal sources such as fungi. The physicochemical properties of chitosan can vary greatly depending on its source.

Chitin is extracted from natural sources via De-mineralization and De-proteination. The purified Chitin is then treated with concentrated alkalis (e.g. sodium hydroxide) to obtain Chitosan.

The process is known as De-acetylation and it affects the final properties of Chitosan such as the extent of positive charge (proportion of amine groups in polymer) and molecular weight.

Chitosan Production

Types of Processed Chitosan

Chitosan is an extermely versatile Biomaterial. It can be processed into various forms such as Micro or Nano Fibers, Micro or Nano Gels, Beads, Films or Capsules, Sponges or Scaffolds, Micro or Nanoparticles, Hydrogel and Gauzes.

Chitosan Quality

Good Quality Chitosan

1.Dispersion of Chitosan Powder in Water

2. Addition of Acid

3. Continuation of Stirring Process

4. Chitosan powder getting dissolve

5. Final Chitosan solution –Transparent and cleared viscous solution

Low Quality Chitosan

Presence of insoluble particles and impurities

Chitosan Powder

Chitosan Flakes

Differentiate based on parameters including

- Physical apparency and purity against low-quality chitosan

- Molecular weight, viscosity, and DDA value

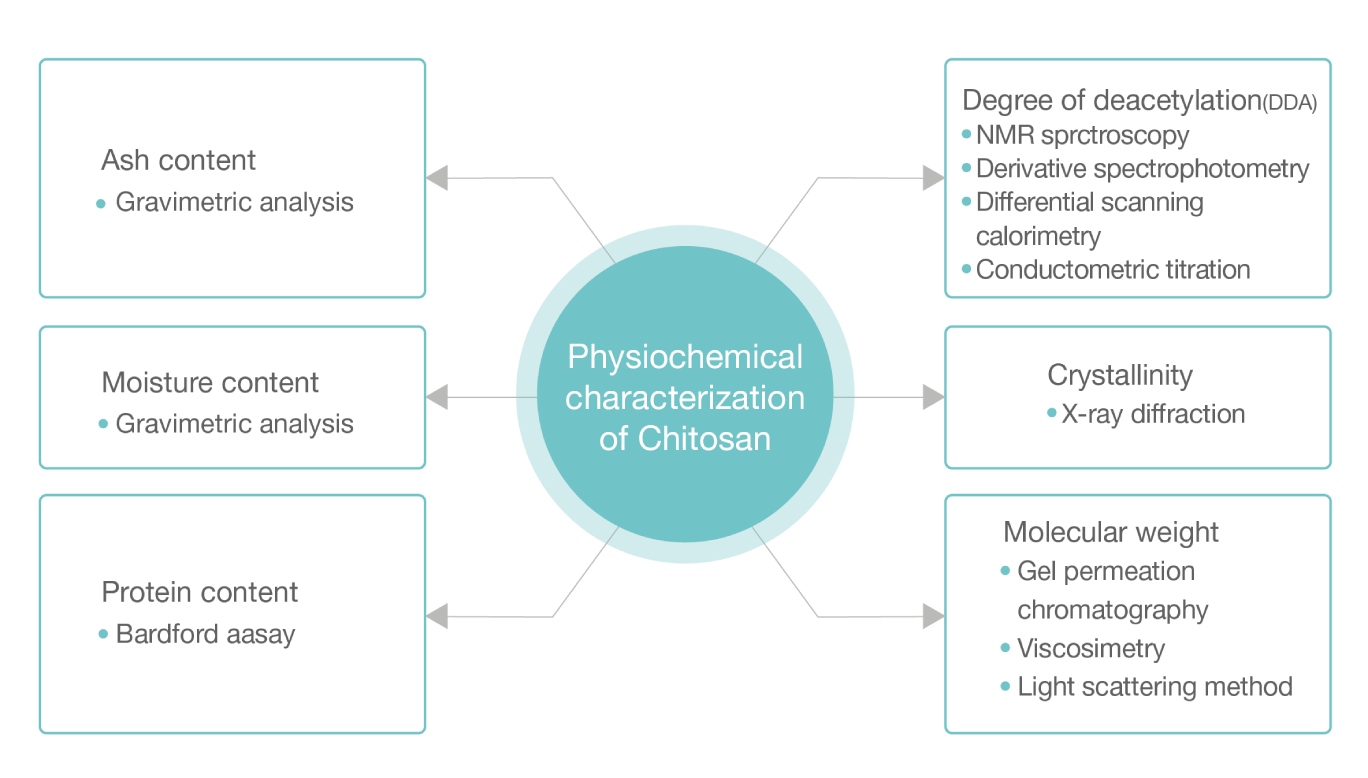

Physiochemical characterization of Chitosan

Chitosan Categories based on DDA Value

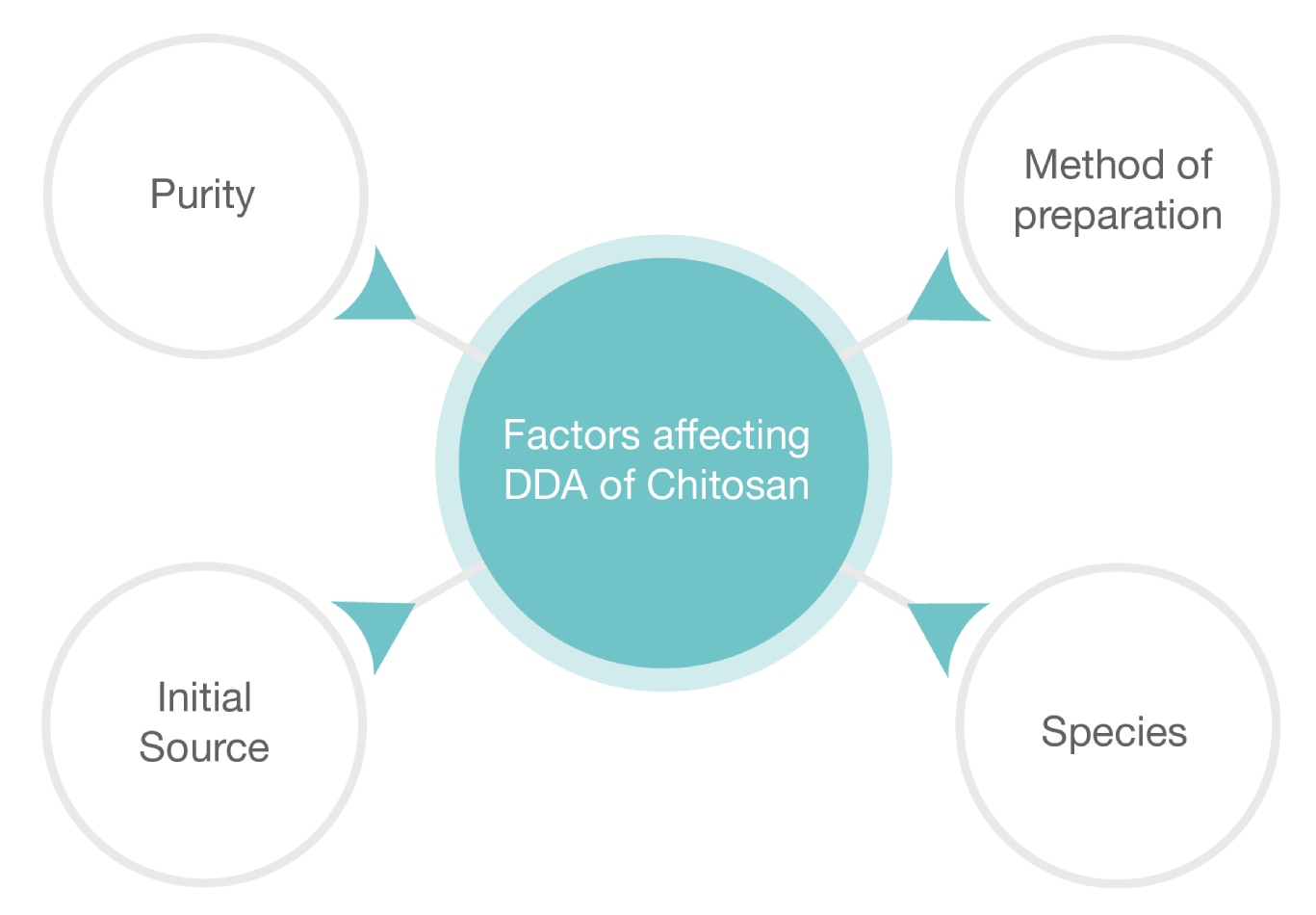

Factors affecting DDA of Chitosan

Significance of DDA in Chitosan

Chemically, Chitosan is a derivative of chitin, consisting of glucosamine and N-Acetylglucosamine chains, and is derived mainly from the endoskeleton of cephalopods, exoskeleton of arthropods and cell membrane of fungi and plants.

Removal of acetyl groups from chitin is described as the process of De-acetylation. Degree of De-acetylation evaluates the content of free amino groups in the molecular structure of chitosan.

When the number of acetamide groups or degree of De-acetylation is more than 50% (ideally 70-90 %) the polymer considered as a chitosan molecule. So, it plays an important role in differentiating between Chitosan and Chitin.

Commercially available chitosan has a wide range of degrees of De-acetylation value. The value of DDA in chitosan varies from 56% to 99% and Chitin with a % DDA = 75 or above is known as chitosan(No and Meyers, 1995).

DDA Measurement Techniques for Chitosan

- Nuclear Magnetic Resonance Spectroscopy

- UV Visible & infrared spectroscopy

- Potentiometric & Conductometric Titration

- Differential scanning Calorimetry

Impact of DDA on Chitosan

DDA is considered a key factor for chitosan molecule as it strongly influences the biological and physicochemical properties. It impacts:

- Solubility & Crystallinity

- Molecular weight & Moisture content

- Cellular responses and Cellular adhesion

- Cell aggregation & Sorption properties

- Heamostatis and Wound Healing properties

- Visosty & Biodegradability

Factors Affecting the Viscosity of Chitosan

- Molecular weight polydispersity index

- Presence of electrolyte & Types of Solvent

- Humidity & Temperature

- Pattern & Degree of deacetylation

- Source & Method of preparation

- Sterilization, Share Rate & Concentration Viscosity of Chitosan

The intrinsic viscosity of 1% chitosan varies from 40 to 5000 cPs depending on several factors.

ASTM Test Methods for Chitosan

| S No. | Test Method | ASTM No. |

|---|---|---|

| 1 | Standard Guide for Characterisation and testing of Chitosan Salts as Starting Materials intended for use in Biomedical and Tissue-Engineered Medical Product Applications | ASTM F2103 - 18 |

| 2 | Standard Test Method for Determining Degree of Deacetylation in Chitosan Salts by Proton Nuclear Magnetic Resonance(1H NMR) Spectroscopy | ASTM F2260 - 18 |

| 3 | Standard Test Method for Determining the Molar Mass of Chitosan and Chitosan Salts by Size Exclusion Chromatography with Multi-angle Light Scattering Detection (SEC MALS) | ASTM F2602 - 18 |

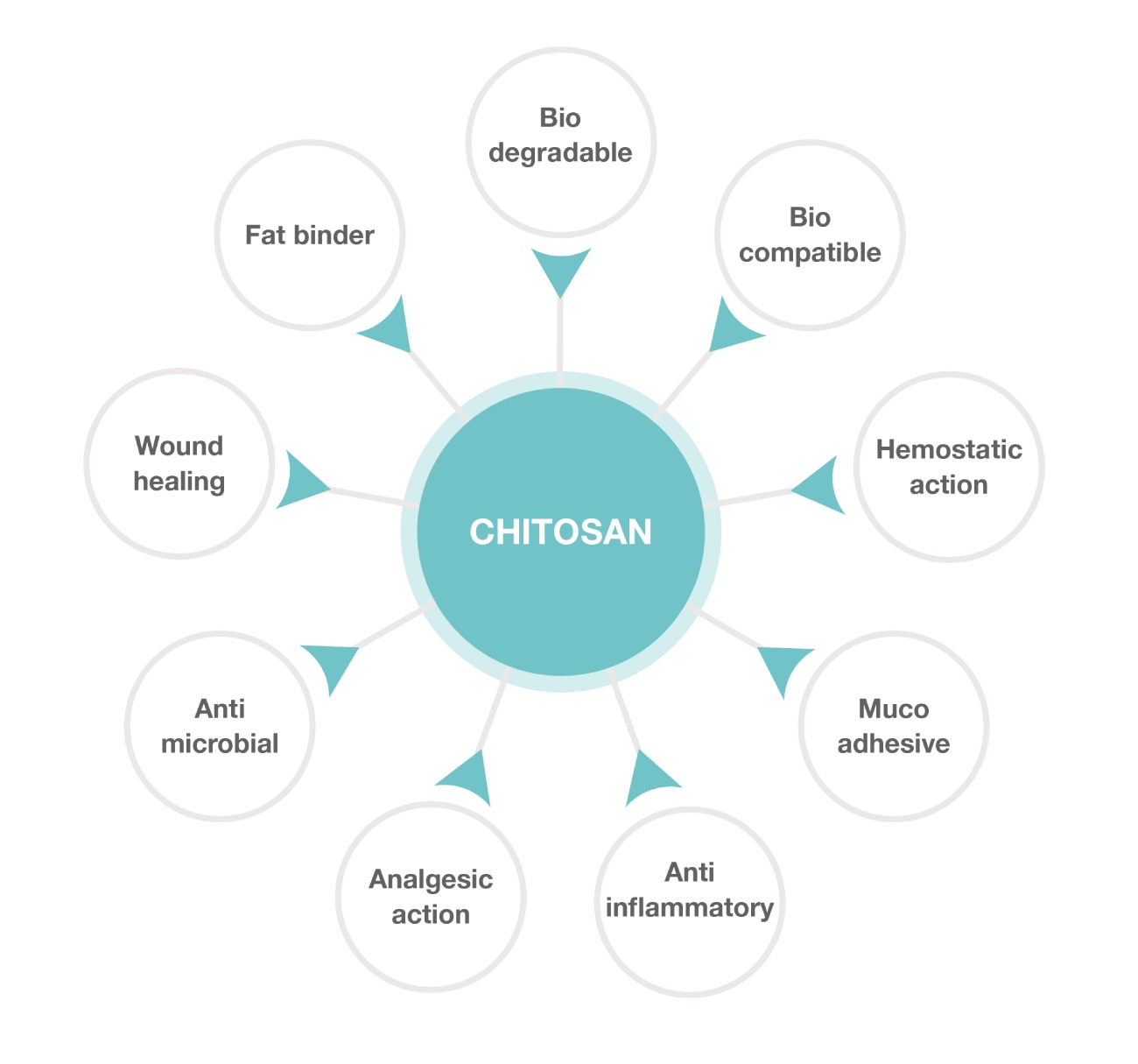

Properties of Chitosan

Chitosan has been extensively studied as a Biomaterial for various applications. Some of its key properties are listed in this image. Due to its Biodegradable and Biocompatible nature, Chitosan has been used in both external as well as implantable medical devices.

As a fat binder, it has been used as a weight-loss agent. The mucoadhesive and viscosity modifying properties make it useful for drug delivery. The Haemostatic, anti-microbial, anti-inflammatory, and analgesic properties make it an excellent wound management material.

Mechanisms of important properties of Chitosan

| PROPERTY | MECHANISM |

|---|---|

| Haemostasis | Cationic chitosan binds to negatively charged blood cells and leads to platelet activation. |

| Anti-microbial | Positively charged chitosan molecules bind to negatively charged microbial cell membranes, which leads to the disruption of microbial membrane, and subsequently the leakage of proteinaceous and other intracellular constituents. |

| Pain control | Chitosan relieves pain through its analgesic effect by reducing concentration of inflammatory mediators (bradykinin) at site of injury. It also absorbs of proton ions released in the inflammatory site to control pain. |

| Wound healing | Chitosan helps in wound healing through multiple pathways such as, polymorphonuclear cell activation, Fibroblast activation, Cytokine production, Giant cell migration and Stimulation Of type IV collagen synthesis. |

| Scar prevention | Chitosan reduces the production of TNF-ß1&2, which are responsible for scarring. Collagen produced in presence of chitosan is fine reticulin-like fibrils rather than mature bands of dense collagen. |

Applications of Chitosan

Chitosan has potential to be a game-changer in the field of advanced wound care, pharmaceuticals and cosmetic industry

Wound Care

- Haemostatic action of chitosan is based on the rapid absorption of blood plasma that leads concentration of erythrocytes and platelet at injured place, followed by platelet activation and erythrocyte coagulation

- Chitosan promotes re epithelization by stimulating the proliferation of dermal fibroblast and inhibiting the proliferation of keratinocytes

- Chitosan act as an antimicrobial agent by causing the leakage of bacterial cell wall through charge-based interaction and inhibition of mRNA and protein synthesis at bacterial nuclei

- Analgesic effect of chitosan comes from the absorption of bradykinin and proton ions at inflammatory site followed by blocking of Arachidonic pathway by phospholipaseA2 inhibition

- Chitosan plays an important role for anti-inflammatory action by produce significant inhibition effect against inflammation mediator such as Interleukin (IL)- 2, IL-4, IL-6, IL-10 and IL-13, cytokines such as TNF-α, NF-kβ expression and AP-1 activation

- Chitosan protects the digestion of skin extracellular matrix by blocking the matrix metalloproteinase-2 expression

Cosmetics

- Chitosan protects the skin from the exposure of UV radiation and act as a sun screening agent ( Sun protector factor around 0.89)

- Chitosan act as a cationic humectant that can easily absorbed to the negatively charged skin surface and hold the moisture content of skin. Moisture absorption capacity enhances with the increase of degree of deacetylation of chitosan

- Polycationic nature of chitosan helps to interact with polyanionic keratin that cause easy film formation around hair fibers. This film improves hair strength ,hair softness, and avoid hair damage.

- Optimum pKa value to inhibit the dental plaque formation around 6.3 and this value comes in the range of chitosan pKa value (5.1-6.5)

- Chitosan has an ability to bind with enamel to create a protective layer that cause reduction of dental abrasion

Pharmaceuticals

- Chitosan has been exploited especially as an excipient in pharmaceutical formulation. Due to its hydrophilic nature it can be used as disintegrating and binder agent for tablet dosage form

- Gel forming capability of chitosan based polymeric matrix helps in control and sustained drug delivery

- Positively charged chitosan easily bind with free fatty acid and block the absorption of lipid in the gut. Chitosan also emulsify the fat and disrupts the lipid absorption in the intestine

- High molecular weight of chitosan and presence of amino and hydroxy group makes it suitable for pharmaceutical excipient as thickening agent , surfactant, emulsifier etc.

Key Sections for Biomedical Applications of Chitosan

Bleeding control & Wound Healing

- Natural Haemostatic Biomaterial

- Act on each phases of wound healing process

- Acceleration of wound healing

- Antimicrobial action

- Anti-inflammatory property

- Causing scar prevention

- Analgesic effect

Disease Diagnosis & Implants

- Bio imaging

- Biosensor

- MRI

- Dental, orthopedic and craniofacial implants

- Contact lens and bone cement preparation

Tissue Engineering & Stem cell Technology

- Cell labeling, cell adhesion, cell encapsulation & Cell Sorting

- 3D Scaffolding & Skin grafting

- Tissue fixation & Enzyme immobilization

- Blood vessel, bone, cartilage, conrneal, intervertebral disc & skin tissue engineering

Drug Delivery & Gene Therapy

- Drug Delivery

- Mucoadhesive Drug Delivery

- Non-viral vector material for gene delivery

- Controlled, Sustained & Targeted

- Nano carrier for DNA and SiRNA Delivery

Wound Healing

How Does Chitosan Help in Wound Management?

- Protects the wounds by shielding from micro-organisms

- Accelerates haemostasis

- Promotes natural wound healing

- Relieves pain

- Reduces scar formation

REFERENCES

- Choi, C., Nam, J.P. and Nah, J.W., 2016. Application of chitosan and chitosan derivatives as biomaterials. Journal of Industrial and Engineering Chemistry, 33, pp.1-10.

- Cheung, R.C.F., Ng, T.B., Wong, J.H. and Chan, W.Y., 2015. Chitosan: an update on potential biomedical and pharmaceutical applications. Marine drugs, 13(8), pp.5156-5186.

- De Queiroz Antonino, R.S.C.M., Lia Fook, B.R.P., de Oliveira Lima, V.A., de Farias Rached, R.Í., Lima, E.P.N., da Silva Lima, R.J., Peniche Covas, C.A. and Lia Fook, M.V., 2017. Preparation and characterization of chitosan obtained from shells of shrimp (Litopenaeus vannamei Boone). Marine drugs, 15(5), p.141.

- Ibrahim, H.M. and El-Zairy, E.M.R., 2015. Chitosan as a biomaterial—structure, properties, and electrospun nanofibers. Concepts, compounds and the alternatives of antibacterials, pp.81-101.

- Pogorielov, M.V. and Sikora, V.Z., 2015. Chitosan as a Haemostatic agent: current state. European Journal of Medicine. Series B, (1), pp.24-33.

- Dai, T., Tanaka, M., Huang, Y.Y. and Hamblin, M.R., 2011. Chitosan preparations for wounds and burns: antimicrobial and wound-healing effects. Expert review of anti-infective therapy, 9(7), pp.857-879.

- Anjum, S., Arora, A., Alam, M.S. and Gupta, B., 2016. Development of antimicrobial and scar preventive chitosan hydrogel wound dressings. International journal of pharmaceutics, 508(1-2), pp.92-101.

- Yuan, Y., Chesnutt, B.M., Haggard, W.O. and Bumgardner, J.D., 2011. Deacetylation of chitosan: material characterization and in vitro evaluation via albumin adsorption and pre-osteoblastic cell cultures. Materials, 4(8), pp.1399-1416.

- Aranaz, I., Acosta, N., Civera, C., Elorza, B., Mingo, J., Castro, C., Gandía, M.D.L.L. and Heras Caballero, A., 2018. Cosmetics and cosmeceutical applications of chitin, chitosan, and their derivatives. Polymers, 10(2), p.213.

- Sultankulov, B., Berillo, D., Sultankulova, K., Tokay, T. and Saparov, A., 2019. Progress in the development of chitosan-based biomaterials for tissue engineering and regenerative medicine. Biomolecules, 9(9), p.470.

A collaborative study with Harvard Medical School

A collaborative study with Harvard Medical School